Huntons were awarded the Design and Build contract for a replacement set of Lock gates at Sunbury in 2014. The works included the survey of the existing lock, full design of a new set of gates, manufacture and installation.

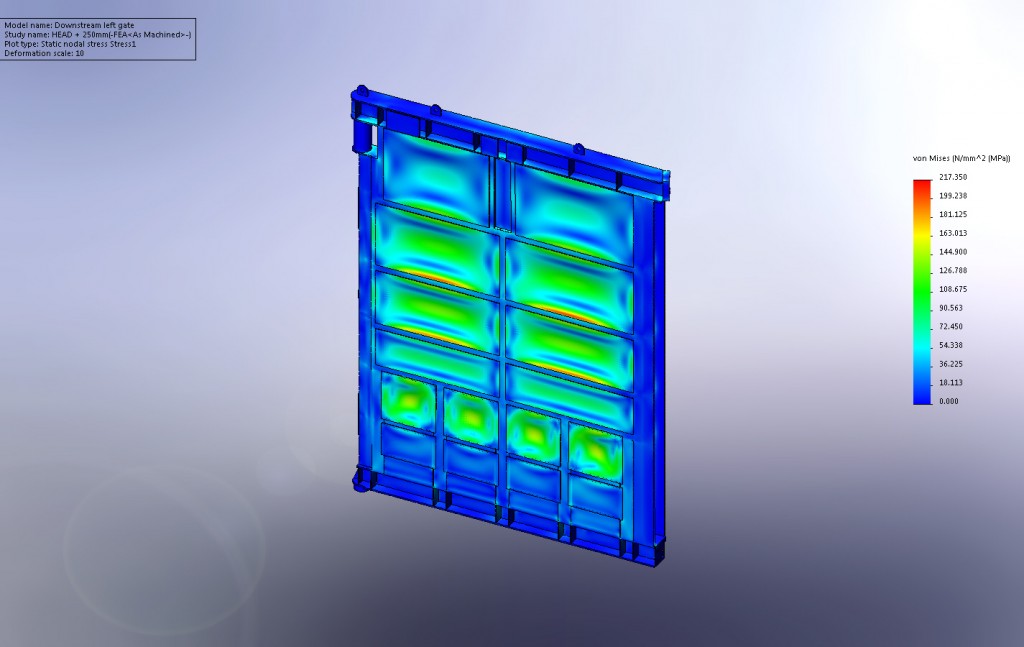

The design was carried out using Huntons experienced team of design engineers, producing a full 3D model of the lock to utilise in our finite element analysis software. this allows us to optimise the design and provides a useful tool for demonstrating what the finished gates will look like for client review. The design was carried out in line with the criteria of Euro-code 3.

Each gate weighs around 8 tonnes and is manufactured in plain carbon steel grade S355 to BS EN 1090 execution class 3. Each gate leaf contains 4 no penstocks operated by hydraulic rams to allow filling of the lock. The gates are filled with foam into sealed chambers to reduce the effective weight when the gates are submerged. The gate uses Orkot thrust blocks to transfer the loads into the civil structure and distribute them evenly. Finally the gates were protected with a duplex system of thermal metal spray and epoxy coating to comply with the highest class in ISO 12944, Class C5-M.

For the installation we used a bespoke lifting frame to allow installation without the need to drain the lock of water and remove the need for crane hires on site. Installation was then carried out using both our site installation team and a diver team experienced in lock gate installation to accurately align the gates.

The gates were finished by modifying and installing the existing walkways, and connecting the hydraulics to the new gates. The gates were then commissioned and handed over to the EA for public use.